Eight tips for creating a good weld

It’s important to know the basic principles to creating a safe, strong and clean weld.

Mathew Hefferan, Field Applications Specialist at Welding Industries of Australia (WIA) shares his top eight tips to create a good weld.

1. Safety

Make sure you have the correct safety equipment, including gloves, a fire-resistant jacket and a helmet.

Designed for the welder who wants protection, performance and comfort at an affordable price, WIA offers the BlueFX & ViewFX auto darkening helmets making it easier for welders to remain safe.

2. Select a process

MIG, Flux Cored, Stick and TIG? Don’t get confused by all the different terms.

Wire welding uses spools of wire fed through a gun, and the constant feed of wire minimises starts and stops. It’s fast, more economical and better suited to welding thin sheet metal.

There are two types of wire welding:

1. MIG (metal inert gas): MIG welding relies on a constant stream of shielding gas to protect the weld from contamination. The limitations to MIG welding are that it can be difficult to use outdoors, and you have to cart around the gas bottle.

2. Flux-cored: Flux-cored welding uses wire that is specifically designed for use with or without shielding gas depending upon the wire being used. Self-shielded wires that can run without the use of gas are suited to outdoor work.

Stick (SMAW)

The best choice for quick repairs. It’s easy to set up and it uses a stick electrode like Austarc 16TC and 12P, so you don’t need a wire feeder. Stick is slower than MIG welding, but often more forgiving when working with dirty or rusty metal. Stick is not recommended for thin sheet metal welding.

Tungsten Inert Gas (TIG)

TIG welding is preferred for architectural or automotive work where the weld has to look good. It’s also a good way to weld thin and sheet metal and achieve a seamless look. TIG is the hardest to learn, but it’s not out of your grasp if you put the effort into it. TIG machines can weld a variety of metals, however if you want to specifically TIG weld aluminium then the a machine with AC/DC capabilities is required, for example the WIA Weldarc 200i AC/DC machine.

If your work requires using a range of different processes, WIA offers various multi-process machines including the Weldmatic 200i, 250i, 350i or 500i.

3. Select the right machine for your weld

There is no single welding process that suits all applications, so you’ll need to choose one that best matches your welding application.

During the selection process the following factors should be considered:

- type of material being welded

- thickness of the material

- the welding position

- type of welding power source and the amount of current available

To help make the selection process a little easier, WIA have put together a selection to assist you in selecting the right welder for your application.

4. Ensure your material is clean

Make sure all the materials are clean. Any oil, rust, paint or mill scale can cause contamination and will result in a poor weld. Before you start the welding process, brush all your equipment, surfaces and materials down to ensure everything is clean.

5. Select the correct settings

Having the correct settings on your welding machine will place a huge impact on the quality of your weld. Every WIA product comes with a product data sheet that will enable you to determine the optimum settings for your weld.

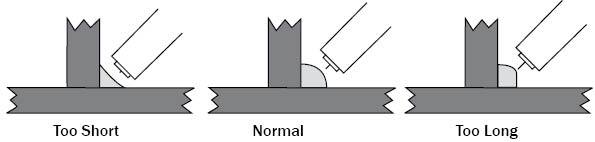

6. Maintain the correct stick out

When MIG welding, it’s important to maintain the correct CTWD contact tip to work distance. If your CTWD is too close, you will find excessive tip wear and if the CTWD is too far, you will experience a reduction in amperage. Both issues will result in a poor weld.

The optimum CTWD for a 0.9mm wire is 10 to 16mm and for a 1.2mm wire is 16 to 19mm.

7. Adjust your machine for every weld

Check your reference chart and adjust your wfs and voltage to suit. Make several practice welds on some scrap metal to ensure you are happy and comfortable with the settings.

8. Practice, practice, practice!

Practice makes perfect. The more welding you do, the better you will become.

Leave a Reply